CONSTRUCTION

WITH THE GRAIN

BuildWithTheGrain.com

ARCHITECTURE

NATURAL DWELLINGS ARCHITECTURE

naturaldwellings.com

DRYWALL SOLUTIONS UNLIMITED

Email: ajwoolstenhulme@yahoo.com

ROOF RESCUE

rescueyourroof.com

TETON CONCRETE SURFACES

facebook.com/tetonconcretesurfaces/

Story By

Julie Fustanio Kling

Photos By

Joe Burns +

Tony Jewell Photography

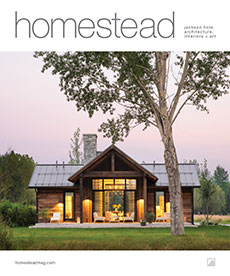

Nestled between pastoral landscapes to the west and rugged mountain peaks to the east sits Yellow Rose Ranch, an Alta neighborhood where a Philadelphia couple staked their retirement claim. Recreational pilot Joe Burns caught a bird’s-eye view of Teton Valley in 2002 while on a solo flight along the Lewis & Clark Trail from Ocean City, New Jersey, to Bend, Oregon. He fell in love with the valley when he stopped for fuel at the Driggs-Reed Memorial Airport and envisioned retiring in this sleepy community.

But first, he had to sell his wife, Dot, on the idea. Her first thoughts of life in the West resembled that of Laura Ingalls Wilder in Little House on the Prairie—until she met a local group of well-read, outdoorsy women that goes by the name of WHALES (Women’s Hiking And Literary Epicurean Society). After that, she never looked back.

Early on, the Burns dreamed of building a rustic log cabin; but in the end, they settled on an elegant, energy-efficient modern design so they could implement the latest technology and lower their carbon footprint. After putting the project on hold when the financial crisis hit in 2008, they finally completed it last August. They’ve now known their builder, Kurt Mitchell, for almost a decade and think of him as a member of the family.

Mitchell, a founding partner of With The Grain, has been building custom homes in Teton Valley since 2004, after moving his company from Colorado. Last year, he engaged Todd Witek as a partner in the company and became a full-service design-builder. Joe Burns and Mitchell share a passion for construction. “I was looking for a builder who would let Dot and me collaborate on the project,” says Burns. With 42 years of major construction experience, he has worked with many general contractors. Selecting one to entrust with his largest personal construction endeavor was a calculated decision. “Kurt is a straightforward and genuine guy. He has a great deal of passion for building homes and a meticulous manner that I can appreciate. I knew we’d make a good team,” says Burns. His wife is quick to agree.

To round out the project’s leadership team, the Burns selected a local architect who advocates for collaboration in a design-build environment. Meghan Hanson, a Passive House-certified architect based in Idaho and Montana, started Natural Dwellings Architecture in 2008 after working with Carney Logan & Burke Architects in Jackson. She enjoys working with clients to combine their goals with high-performance design elements, including highly insulated and air-sealed structures and passive lighting, heating and cooling options. She received recognition early on in her career for an innovative straw-bale house she designed and built for herself.

“Joe is a researcher who has a methodical, mechanical mind,” Hanson says. “This house was a wonderful learning experience because all involved passionately believed in utilizing environmentally conscious, energy-efficient strategies.”

One of the materials she researched and used in the process is ROXUL insulation, a spun rock mineral fiber comprising basalt rock and recycled slag, a byproduct of steel and copper. It offers excellent fire and water resistance while providing sound absorption and thermal qualities. It was an integral part of a very sophisticated wall system.

The exterior of the home’s creative H-shaped design is made of Corten steel and Charwood™ siding, a product made by a Japanese process known as shou sugi ban, which was invented to create weather-, fire- and pest-resistant material. In this case, it is just a facade. The real weather barrier is the rainscreen underneath the exterior steel and siding, which brings air up and moisture down. “Meghan provided the most thorough and detail-oriented architectural plans I’ve ever seen,” says Mitchell. “They provided a solid foundation for our design-build collaboration.”

Inside the house, it is as quiet as a walk in the forest, thanks to the triple-paned windows, an impenetrable air envelope and an exceptional insulation package. With a light and airy feel, the great room boasts large windows with a view of Fred’s Hill at Grand Targhee Ski Resort and two ambiance-building elements—a propane fireplace and a wood-burning stove.

Concrete dominates the floors throughout the home. “Joe and Dot wanted the concrete floors to have a light sheen to them, one that would stand the test of time,” says Mitchell. “We selected Teton Concrete Surfaces for their expertise in concrete floor polishing.” The floors create a pattern that, together with the functional yet decorative soffit, frames the open living space. The soffit gives the room an intimate feeling, while also providing a buffer for canned lighting.

The home features drywall-wrapped windows and door jambs and a smooth drywall finish. To achieve this labor-intensive look, known in the business as a Level 5 finish, Drywall Solutions craftsmen worked meticulously with genuine concern and care throughout the process.

The home’s roof is a blend of Corten standing-seam metal and cedar shakes. Mark Franklin of Roof Rescue seamlessly transitioned between roof areas and from one roofing material to another to provide watertight peace of mind.

The south wing of the house was designed for the Burns’ two kids and grandchildren, with a separate living room, bunk room and guest bedrooms. A walnut guest bed headboard mirrors the shape of the Big Hole Mountains visible through a window above it. The bed frame was cut from the same slab that local woodworkers used for the dining table and a bench in the mudroom. Because of the home’s geometric design, when the guest quarters aren’t in use, the Burns can isolate that portion of the home, turn off its heat and hot water and realize energy savings.

Throughout the entire home, a glycol-water mix runs through pipes underneath the floors, providing hydronic heat, even in the garage. A nod to Burns’ mechanical background, the crawlspace floor is concrete, so he can comfortably access the home’s mechanical workings. And, there is a live roof above the entryway where wild grass grows. Every detail has been considered, from making sure the wood grain aligns in the built-in cabinetry to using zinc terrazzo strips in place of the control joints and at the concrete transitions to the maple floor.

“When you have homeowners like the Burns participating in the process, the outcome is almost guaranteed,” Mitchell says.